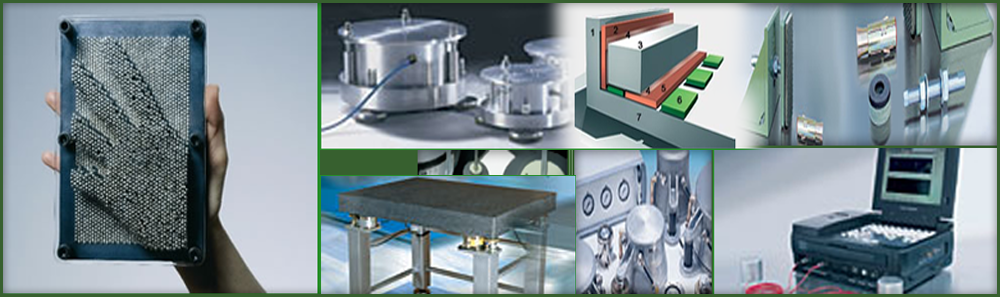

NC-Drill Chuck

Application:

The uni-body NC-Drill Chuck is most suitable for CNC Machines.

Features :

a. Shorter Length

b. Less overhang

c. Good tool life

d. Less Regrinds

e. Wrench tightening

f. High Concentricity (0.04 T.I.R.)

| Comparison between Normal Drill Chuck & NC Drill Chuck | |

| NC Drill Chuck | Normal Drill Chuck |

| Built in design eliminates possibility of drill slipping off from the arbor. | Drill breakage & slippage of drill before through hole drilling. |

| No Drill breakage due to reverse thrust.No Flying of Drill at spindle stops. | No Flying of Drill at spindle stops. |

| No flying of drill Chuck from Arbor mounts. | Flying of drill when spindle stops. Sudden stop of spindle/ reverse of rotation (by error) |

| Gripping power 3 times than normal Chuck. | No flying of drill Chuck from Arbor mounts. |

| Gripping power 3 times than normal Chuck. | |

| Disengagement from Taper either from short morse or Jacob's. | |

| Comparison data of drill chuck tightening torque. | |||

| Type of Drill Chuck | Method of tightening | Twisting moment | Comparison % |

| DC 113 ( Normal) | BY Hand | 6.9 Nm | 100 |

| NC DC 113 | By Wrench | 21.8 Nm | 300 |